Introduction

The construction industry is undergoing a profound transformation as innovative materials inspired by biological systems increasingly replace or augment traditional building components. One of the most promising frontiers in this realm is self-healing walls using living materials—biological or bioengineered substances capable of sensing damage and repairing themselves autonomously, much like living organisms heal wounds. This emerging technology holds the potential to drastically reduce maintenance costs, extend building lifespans, improve environmental sustainability, and enhance resilience against wear, cracks, and environmental stresses.

Self-healing walls leverage living microbes, fungi, or engineered cells embedded within construction materials, which activate biochemical and physical processes to seal cracks, restore structural integrity, and even adapt to environmental conditions. Such materials reflect a paradigm shift from static, inert building components to dynamic, regenerative systems that function as part of a living architecture.

This comprehensive analysis explores the science, technologies, design principles, applications, benefits, challenges, and future potential of self-healing walls based on living materials. It highlights how integrating biology with material science creates revolutionary construction solutions aligned with global sustainability goals and smart building visions.

1. The Science Behind Living Self-Healing Walls

1.1 Engineered Living Materials (ELMs)

Engineered living materials (ELMs) are biologically based building blocks that incorporate living cells capable of sensing damage and responding to it through healing processes. These living materials combine genetic engineering, microbiology, and materials science and exploit natural biological capabilities such as regeneration, biomineralization, and growth.

For example, bacteria embedded in wall materials can detect cracks or fissures and produce calcite (calcium carbonate) to fill and seal them, mimicking natural healing observed in bone or coral reefs. Similarly, fungal mycelium networks serve as scaffolds that grow and repair structural damage while providing insulation and environmental buffering.

1.2 Microbial Biomineralization and Bio-Composite Mechanisms

A central healing mechanism in many living walls involves microbial biomineralization: microorganisms precipitate minerals that physically fill cracks and reinforce damaged zones. Bacteria such as Sporosarcina pasteurii produce calcite upon exposure to urea and calcium sources, effectively sealing concrete fissures and improving durability.

Alongside biomineralization, bio-composites combining organic fibers (like mycelium) with mineral substrates enable walls to regain stiffness and strength. These composites can be grown under ambient conditions and possess regenerative qualities, growing back after damage and resisting microbial degradation.

1.3 Longevity and Multi-Cycle Healing

Recent advances have enabled living materials where embedded microorganisms remain viable for extended periods—often weeks to months—allowing several cycles of sensing and repair. This durability over time is critical for large-scale construction applications, where materials must function robustly under variable weather, mechanical stress, and aging.

2. Technologies Enabling Self-Healing Walls

2.1 Genetic Engineering of Microorganisms

Scientists genetically engineer bacteria and fungi to enhance their healing performance, controlling the production of binding minerals, antimicrobial properties, and response sensitivity. Advanced synthetic biology tools help create microbial strains tailored to specific environments, with safety measures ensuring ecological compatibility and human health.

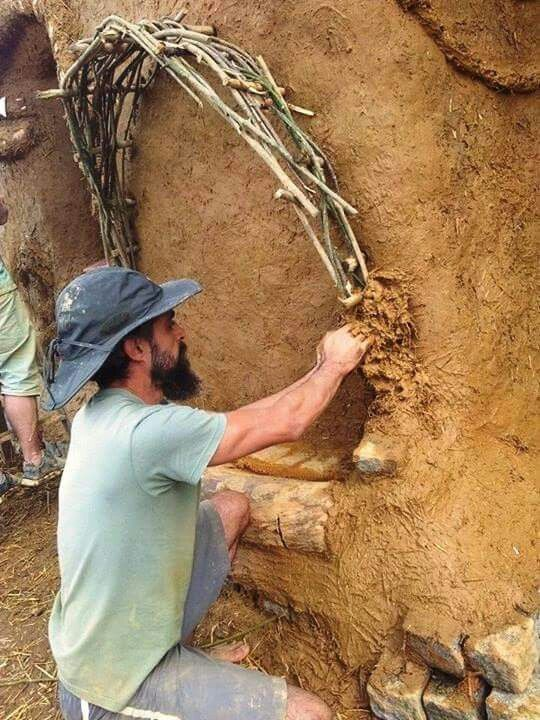

2.2 Living Building Materials (LBMs) Fabrication

LBMs are fabricated by combining scaffolding materials (such as sand, gelatin, or bio-based polymers) with living cells, forming stiff living materials (SLMs) that can self-regenerate. Manufacturing involves inoculating substrates with microbial cultures and controlling growth to form durable, load-bearing panels or bricks.

2.3 Microencapsulation Techniques

To protect microorganisms and extend shelf life, healing agents can be microencapsulated within biodegradable shells—microcapsules dispersed throughout the wall matrix rupture upon mechanical damage, releasing bacteria and nutrients to trigger self-healing.

2.4 Integration with Smart Monitoring

Coupling self-healing walls with IoT sensors and AI-enabled systems enables active monitoring of wall integrity, environmental conditions, and microbial health. Smart systems can optimize healing by regulating moisture, temperature, and nutrient supply or signaling repair needs to building maintenance teams.

3. Design and Applications

3.1 Residential and Commercial Building Walls

Self-healing living walls can replace or complement traditional concrete and mortar walls, reducing cracks caused by thermal expansion, settlement, or mechanical impact. Applications extend from single-family homes to commercial buildings, promising lower repair cycles and enhanced resilience.

3.2 Infrastructure and Public Works

Bridges, tunnels, roads, and retaining walls greatly benefit from biomineralizing self-healing materials, which reduce deterioration, extend service life, and decrease maintenance costs—especially critical in climates with harsh weather or heavy usage.

3.3 Green and Biophilic Architecture

Self-healing walls often integrate organically with green building principles by incorporating natural materials and promoting indoor environmental quality. Mycelium-based walls also provide thermal and acoustic insulation, enhancing occupant comfort.

3.4 Historical Preservation and Retrofit

Living materials enable restorations that are sympathetic to historic structures, allowing repair without aggressive mechanical interventions. Their adaptable and regenerative qualities suit the sensitive conservation of heritage buildings.

4. Benefits of Self-Healing Walls Using Living Materials

4.1 Extended Material Lifespan and Reduced Maintenance

By autonomously repairing microcracks before they propagate, self-healing walls increase structural longevity and safety, reducing costly repairs and downtime.

4.2 Environmental Sustainability

LBMs reduce the environmental footprint of construction by decreasing the need for cement production (a major CO2 emitter) and lowering material waste. They also utilize renewable resources or upcycled biomass, enabling circular economy models.

4.3 Energy Efficiency and Indoor Air Quality

Some engineered living walls actively contribute to air purification and humidity regulation, improving indoor environmental quality. Their porous and bioactive natures facilitate better thermal insulation and moisture buffering.

4.4 Adaptability and Resilience

Living walls can respond dynamically to environmental changes, adapting their properties (e.g., moisture retention, strength) as needed, making buildings more resilient to climate variability.

5. Challenges and Limitations

5.1 Scaling Production and Cost

Large-scale manufacture of living materials requires controlled bioreactors or growth chambers and integration with conventional construction workflows. Current costs remain higher than traditional materials, though expected to fall with technological advances.

5.2 Longevity and Environmental Stability

Maintaining microbial viability over years, exposure to pollutants, varying humidity, temperature extremes, and UV radiation poses significant scientific and engineering challenges.

5.3 Regulatory and Standardization Issues

Building codes and safety certifications have yet to fully incorporate LBMs and living walls, delaying widespread adoption and hampering market confidence.

5.4 Performance Limitations

Current LBMs may lack the immediate compressive strength and robustness of traditional concrete, limiting their use in high-load structural elements without hybridization.

6. Future Trends and Innovations

6.1 Integration with Artificial Intelligence and IoT

Smart self-healing walls will incorporate embedded sensors and AI to modulate healing stimuli and system health, enabling predictive maintenance and adaptive building management.

6.2 Biofabrication of Custom Properties

Advancements in synthetic biology will allow biofabrication of walls suited to local climate, pollution levels, and building use—tailoring strength, permeability, and other traits on demand.

6.3 Hybrid Living-Inorganic Materials

Combining living materials with traditional synthetics in composites will combine benefits of both, enhancing durability and healing capacity.

6.4 Environmental Remediation

Future walls may absorb pollutants, sequester carbon, or resist microbial colonization harmful to human health, contributing actively to the building’s ecological function.

Conclusion

Self-healing walls using living materials are poised to revolutionize the construction industry, unlocking new levels of sustainability, resilience, and intelligent performance. Blending biology, material science, and engineering, these novel walls embody regenerative design principles that parallel nature’s time-tested ability to heal and adapt. While challenges remain in scalability, durability, and regulation, ongoing research promises pathways to mainstream adoption.

As urban areas seek greener, longer-lasting infrastructure and healthier indoor environments, living walls offer a tangible, innovative solution, signaling the future of architecture where buildings become active, responsive partners in their own maintenance and environmental stewardship.

For architects, developers, and pioneers in sustainable design, embracing self-healing living walls opens exciting opportunities to build smarter, cleaner, and more resilient habitats for generations to come.

For expert consultation on designing, fabricating, or integrating self-healing living walls into architectural projects, contact:

Mishul Gupta

Email: contact@mishulgupta.com

Phone: +91 94675 99688

Website: www.mishulgupta.com